The UK’s most advanced composites manufacturer – Creative Composites based in Lisburn, Northern Ireland is delighted to be supplying innovative SMC parts for a new revolutionary electric light commercial van.

The unique range of SMC compression moulded parts have been chosen for longevity and light weighting to improve fuel efficiency, lower vehicle operating costs and extend the vehicle’s zero power range. The composites manufacturer has been working in collaboration with one of the UK’s leading OEM’s for several years. Together they have developed SMC parts for use in a range of iconic and ground-breaking vehicles, manufactured at the UK’s only dedicated electric vehicle factory. The parts include SMC front fenders and doors, designed to offer longevity, flexibility and robustness against everyday dents and knocks.

Richard Ennis, Chairman, UK based Creative Composites, “These hybrid vehicles are cleverly designed to optimise performance and styling whilst reducing emissions and operating costs. Our specialist Vehicle Design Team has been working closely with our client’s engineers to develop, design, prototype and validate various composite SMC parts for their new pioneering van. “It is exciting to collaborate with global leaders in vehicle design and to supply innovative SMC parts that help improve the performance of zero emission vehicles.”

SMC compression moulded parts deliver a range of important benefits for a wide range of vehicles including cars, vans, trucks, rail, bus and construction equipment. Increasingly vehicle manufacturers are turning to SMC composites to provide the crucial weight savings required to improve fuel efficiency and zero emission vehicle range. However, with the added benefits of class ‘A’ surface finishes, unlimited design flexibility, impact, heat and corrosion resistance combined with composite’s ability to aid connectivity and noise reduction, SMC continues to gain market share over steel, aluminium and other plastic alternatives.

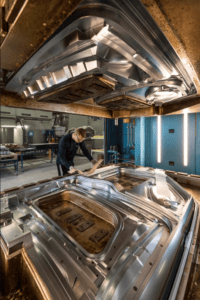

SMC manufacturing offers precise dimensional accuracy, repeatability and fast cycle times. To fully exploit their huge compression moulding presses, (with up to 3000 tonnes of pressure) the Creative Composite engineers concentrate on optimising design for manufacture and component consolidation, to achieve vital cost savings for clients.

Richard Ennis, Chairman, explains: “We continually invest in our world class production facility to remain at the cutting edge of advanced composite manufacturing. This primarily guarantees our clients the highest level of quality and surface finish. However, it is our engineering expertise combined with advanced technology that differentiates our service and ultimately generates cost savings for clients. Value engineering is vital, we work with clients from the outset to help develop and optimise their ideas for manufacture. This ensures they get the most out of composites, superb quality and precise components, assembled, bonded, painted ready for installation on their production lines.”

Looking to the future, Creative Composites are looking forward to further global collaborations with automotive, van, truck, bus, materials handling equipment and last mile delivery OEM’s. The company is focused on improving the sustainability and eco credentials of vehicle components by offering a range of innovative, new lightweighting solutions including low-density SMC and ultra-low density SMC.